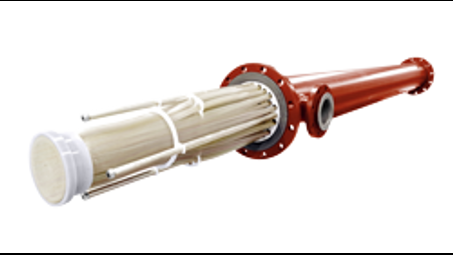

shell and tube heat exchangers are used mostly in the chemical processing industry for heating, cooling, condensing, and evaporating highly corrosive liquids and gases.

AMETEK Fluoropolymer Product shell and tube heat exchanger was the first heat exchanger developed using fluoropolymer tubes and the patented honeycomb tube to tube sheet joint which has been successfully used for over 55 years.

Sulfuric Acid is the chemical most used with Ametek Fpp heat exchangers. The process of making sulfuric acid can vary, but any company dealing with the manufacturing process has a high potential for the use of a fluoropolymer heat exchanger in their process.

Other Acids commonly requiring fluoropolymer heat exchangers are Hydrochloric, Nitric and Hydrofluoric Acids. Another chemical manufacturing industry fluoropolymer heat exchangers are used in is the Chlor-Alkali manufacturing process.

Khaleel basha

Add your answer:

What are fireworks shot out of?

The only ones that need to be fired 'out-of-something' are rockets (use a tube that the stick fits into) and aerial shells. Aerial shells need to fired from a mortar tube which is a card, plastic, fibreglass or metal tube that has the same inside diameter as the shell to be launched.

Which tube to use to draw pt inr labs?

blue (citrate) tube

What is fin tube heat exchanger?

A heat exchanger composed of finned tubing. Finned Tube----Finned tube heat transfer principles and selection principles Finned tubes, also known as fin tubes or finned tubes, the English name is "Fin Tube" or "Finned Tube", also sometimes called "Extended Surface Tube", which extended surface tube. As the name implies, is a finned tube on the original surface of the tube (irrespective of the outer surface or inner surface) of processing of a number of fins, the original surface is extended to form a unique heat transfer components. Why use finned tubes? Processing of the original surface of the fin can play what role? To answer this question, but also from some of the basic principles of heat transfer process to start. First,To introduce a heat transfer on the definition: solid surface in contact with the fluid, and it is called convection heat transfer between the heat exchanger. We are most familiar with is the convective heat radiator and air between the outer surface of the heat exchanger. Life experience tells us: Radiators area is larger, the higher the surface temperature (i.e., surface temperature and the greater the temperature difference between the air), the longer the heating time, the greater the heat exchange, Room more warm. This shows that heat and convective heat transfer area is proportional to the temperature difference and the proportional and proportional to the time. To compare the strength of convective heat transfer case, we need to define a physical quantity: called "heat transfer coefficient." Is the heat transfer coefficient per unit area and temperature (the temperature difference between the wall and the fluid), the convective heat transfer per unit time. The unit is J / (s. m. ℃) or W / (m. ℃). Convective heat transfer coefficient h is commonly used symbols. Heat transfer coefficient depends mainly on the following factors:  the type of fluid and physical properties: such as water and air is totally different, the heat transfer coefficient vary considerably;  whether the process fluid in the heat exchanger phase change, that is, whether the boiling or condensation occurs. If the phase transition occurs, then it will greatly enhance the heat transfer coefficient; 2  also, and fluid velocity and solid surface shape. And so on. The size of the convective heat transfer coefficient is mainly through experimental studies to determine, given below a set of common cases Range of values:  water vapor condenses: h = 10000 --- 20000 W / (m * ℃)  boiling water: h = 7000 --- 10000,,,,,  water convection: h = 3000 --- 5000,,,,  forced convection of air or gas: h = 30 --- 80,,,,,  natural convection of air or gas: h = 3-10 ,,,,, Thus, The heat transfer coefficient under different circumstances the difference is huge. Keep in mind that the range of values ​​of the heat transfer coefficient, which is the understanding and subsequent selection of finned tubes is a great useful. The following will discuss a concrete example of the heat transfer device: With a heat exchanger with hot water heated air, hot water flowing in the pipe, the air flow in the tube. Such as heating with hot air curtain or automobile radiator (radiator) belong to this type of heat transfer that heat hot water to pass through the wall of the tube cold fluid - air. Thus, the heat transfer process with the partition of the two sides of convective heat transfer process tightly linked. For the above example: pipe water side convective heat transfer coefficient is approximately 5000, while the tube air-side heat transfer coefficient is about 50, a difference of 100 times. As the air-side heat exchanger "capacity" is far below the water side, which limits the water side heat exchanger "capacity" of the play, such that the air-side heat transfer process in a "bottleneck", limiting the increase in heat transfer. In order to overcome the air side of the "bottleneck" effect, in the installation of air-side outer surface of the fin would be a wise choice. After the installation of the fins, the air-side heat transfer area of ​​the original has been greatly expanded, Mi fill the air-side heat transfer coefficient is low, and makes heat transfer greatly improved, as shown in the following figures. The role of the fins on the installation can also use the following example to illustrate more vividly: border crossings in an immigration office, assuming there are ten ports Party Inspection mouth, release 5,000 people per hour, while the B port is only one wicket mouth, and run very slow release of 50 persons per hour only. Thus, the B-side passenger clearance has become a bottleneck, making the party's "ability" can not play. In order to improve customs clearance flow, the most effective way is to open a few B-side inspection port. This principle is the same as the installation of the fins. Finned tubes in the understanding of the principles and the role of the future, and in what situations selection finned tubes, are the following principles: (1) If both sides of the heat transfer coefficient of the tube a big difference, you should install the side heat transfer coefficient is small fins. Example 1: boiler economizer tube walking through water, drain pipe flue gas side fins should be used. Example 2: air coolers, tube go liquid, drain the air tube, the fins should be added to the air side. Example 3: steam generator tube is water boiling, take the gas tube, fins should be added in the flue gas side. It should be noted, in the design, the heat transfer coefficient should be placed on the side of the tube in order to facilitate the installation of the fins. (2) If the tube side heat transfer coefficient is very small, in order to enhance heat transfer fin should be installed on both sides at the same time, if the structural difficulties, the two sides can not add fins. In this case, if only the side add fins to increase heat transfer effect is not obvious. Example 1: The traditional tubular air preheater, take the air tube, the tube take the fumes. Because it is a gas on gas heat exchanger, the heat transfer coefficient is very low on both sides, plus finned tube very difficult, had run out of the tube. Example 2: heat pipe air preheater, although still smoke heated air, but the gas and air are flowing in the tube, so the gas side and air side can easily adopt finned tube, so that the heat transfer greatly increased. (3) If the tube side heat transfer coefficient is large, it is not necessary to use finned tubes. Example 1: water / water heat exchanger, heated with hot water, the two sides are sufficiently high heat transfer coefficient, it is not necessary to use the finned tubes. However, in order to further enhance the heat transfer, can be used instead of threaded pipe or bellows fluorescent tubes. Example 2: plant condenser tube condensation of water vapor, the water pipe to go. Both sides of the heat transfer coefficients are high, in general, without the use of finned tube. Key Works: Finned Tube, Fin Tubes, Tubos Aletados, heat transfer http://www.ts-aceroinoxidable.com/tsaceroinoxidablecom/html/productlist/finnedtube.html

What is the use of gas measuring tube?

barometer

Fbs collection tube use?

gray

How many types of heat exchangers are there?

Heat exchangers are devices that allow heat to be transferred between two or more fluids of different temperatures (vapors, liquids, or gases). The heat transfer process can be liquid-to-gas, gas-to-gas, or liquid-to-liquid, and it can happen through a solid separator or direct fluid contact, depending on the type of heat exchanger used. Other design features, such as construction materials and components, heat transfer processes, and flow configurations, aid in classifying and categorizing the various types of heat exchangers accessible. Heat exchanger makers offer a wide range of heat exchanging devices designed and manufactured for use in both cooling and heating processes and find applications across a wide range of industries. This blog examines the numerous types and designs of heat exchangers, as well as their functions and mechanics. This blog also discusses the factors to consider when choosing a heat exchanger and the most popular applications for each one.

Disadvantages of shell and tube heat exchanger?

it is difficult to remove the scales. we cannot use scale forming fluid through the shell because if we pass, the scales are formed and it corrodes the shell.

Why most of the heat exchangers are made use of forced convection?

Better heat transfer than natural convection. When compared to water or liquid cooled heat exchangers, the argument could be made that air is a cheaper cooling medium.

Why Don't we use odd number of tube passes in Shell and Tube Heat Exchanger?

It is difficult from cleaning point of view. Both end chambers have to be removed so as to clean the heat exchanger with odd nos of passes. Thanks & Regards Priyanka Karkera

How are tube heat exchangers designed?

Tube-type heat exchangers are designed using tubes to contain and convey either the exchange medium or that which needs heating or cooling. Let's look at an example and it will be more clear. In a condenser below a steam turbine, the "used steam" comes out of the turbine and passes across many tubes through which cool water is being pumped. The steam condenses into water as heat is exchanged with the tubes, which were cooled by the water being pumped through them. Use the link (provided) to the Wikipedia article on the surface condenser for some great drawings and a more detailed explanation.

Why do we use test tube?

we use test tube to hold chemicals and heat and chemicals.

Heat Exchanger Types and Uses?

heat sink classified according to the shape, the shape is how to dissipate within the selected heat sink that is the main intension here,, k type l type rectangular triangular chassis i know this much u can down load the pdfs for the types how to select the required heat sink 9844354439

Q: What industries commonly use Admiralty Brass Tubes?

A: Admiralty Brass Tubes are widely used in heat exchangers and condensers in power plants and refineries.

What is AEM type heat Exchanger?

I'm just concluding a work in which I had to design a shell and tube exchanger for condensation of a mixture of gases and vapor at low pressure. That was the type I chose. AEM is a type of shell and tube heat exchanger, according to TEMA standards. They use 3 letters to describe the configuration of the heat exchanger. First letter refers to the front head, second letter to the shell type and third letter to the rear end stationary head. So in this case, with a type A you would have: A for channel and easily removable cover. E as it is a one pass shell and M because you have a fixed tubesheet with a rear end in bonnet shape.

Where do you make use of good heat conductors?

Heat exchangers use heat conductors to transfer heat from one liquid to another.Refrigerators/freezers use heat conductors to cool the inside of your fridge.Disc brakes are made from materials that are good at heat conduction to keep them cool.The processor on your computer has a heat sink on it which allows the heat from the processor to be dissipated.Radiators are made of metals that are good at conducting heatThe element in a kettle is used to conduct heat.

What tester do you use to test an heat exchanger?

There are different types of heat exchangers. To get an answer the type of exchanger and what type of test you want to do should be stated.

Why tube light is black in both end after use?

due 2 heat